ISO/TS 16949 Automotive Industry Quality Management Systems

Posted in ISO Standards

ISO/TS 16949, in conjunction with ISO 9001, defines the quality management system requirements for the design and development, production and, when relevant, installation and service of automotive-related products.

ISO/TS 16949 is applicable to sites of the organization where customer-specified parts, for production and/or service, are manufactured.

Supporting functions, whether on-site or remote (such as design centres, corporate headquarters and distribution centres), form part of the site audit as they support the site, but cannot obtain stand-alone certification to ISO/TS 16949.

ISO/TS 16949 can be applied throughout the automotive supply chain.

Requirements of ISO/TS 16949:

- Scope

- Normative Reference

- Terms and Definitions

- Quality Management System

- Management Responsibility

- Resource Management

- Product realization

- Measurement, analysis and improvement

Benefits of ISO/TS 16949

- Gain your licence to trade internationally and expand your business

- Improve processes to reduce waste and prevent defects

- Remove the need for multiples certificates for vehicle manufacturing

- Integrate ISO/TS 16949 with other management systems

- Demonstrate compliance to win new business and investment prospects

How Can Nexus TAC Help?

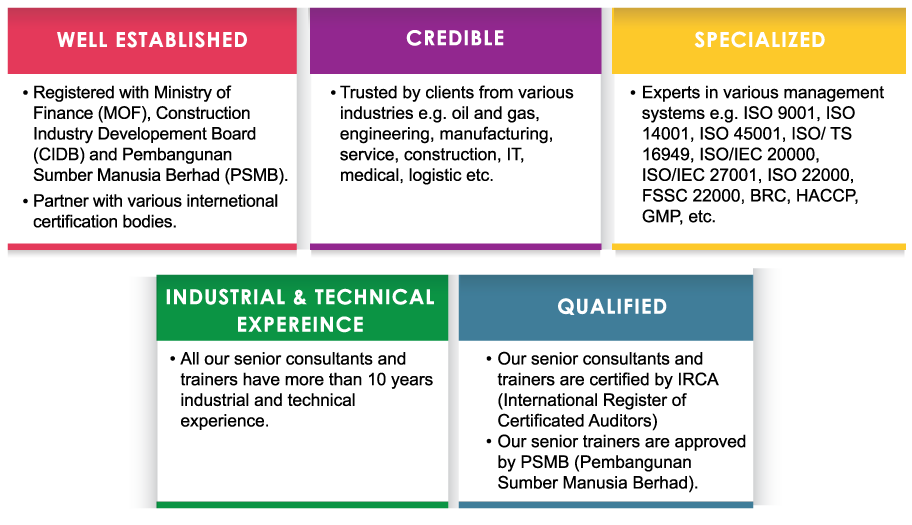

Nexus TAC, ISO consultant in Malaysia, provides management system training and consultancy services. We offer specialized expertise and extensive practical experience to assist client in developing management systems from the initial concept to establishment and successful implementation of the management systems.

We use the following consultation approach to assist you in achieving certification:

- Identify areas requiring improvement or development within your current Management System

- Prepare a strategic action plan, in conjunction with your company personnel, to address those improvement areas and assist with the communication of these requirements to key personnel at all levels

- Provide system-related trainings for your company personnel to create awareness and provide them with the necessary knowledge and skills in the implementation of systems

- Provide assistance and advice on the development and implementation of systems, including preparation of documentation

- Advise and assist, if required, with the preparation and submission of applications to your certification body

- Assist with the development of internal auditing procedures and training

- Conduct internal audit to ensure the effective implementation of the management system prior to final audit by your certification body

- Conduct Management Review Meeting to review performance of management system and identify areas for improvement prior to final audit by your certification body